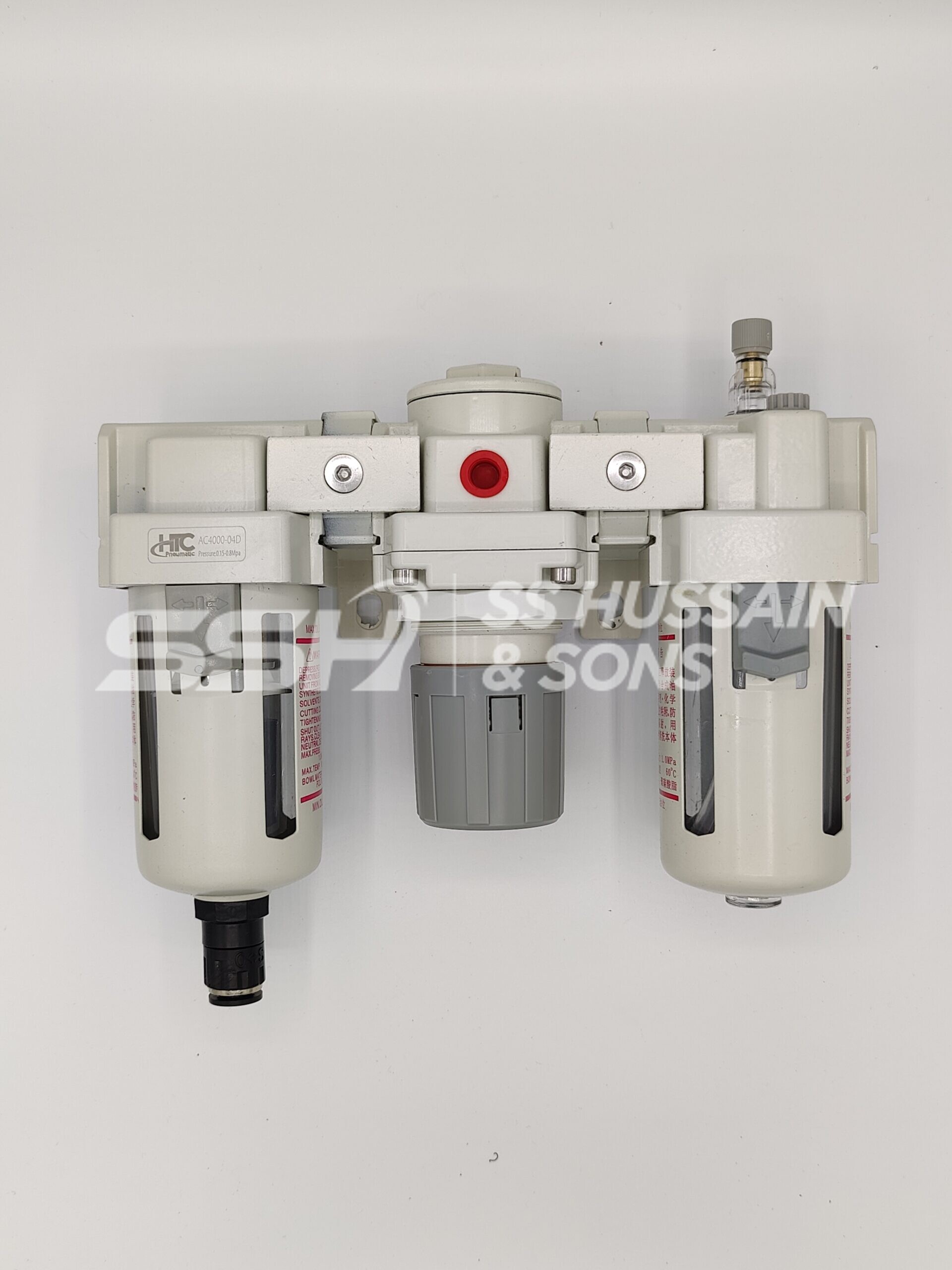

Filter, regulator, and lubricator are the three parts that make up an F-R-L system. Pneumatic equipment relies on each component to carry out its intended tasks and keep operators safe. By combining them into one device, these features make it easier to install and maintain, and they also guarantee that the air that powers your equipment is clean, controlled, and lubricated.

COMPONENTS OF AIR PREPARATION UNIT

1. Filter: Purifying Air

An F-R-L system begins with the filter. Its principal function is to purge the compressed air entering the system of any impurities. Pneumatic tools and machinery can be severely hindered in their functioning by these pollutants, which can include dust, grime, water vapor, and oil particles.

How It Works:

The filter unit receives compressed air and uses it to pass it through a fine-mesh filter. Particles and moisture are caught in a bowl at the base of the filter as air flows through this mesh. After the filter unit finishes cleaning the air, it is sent on to the regulator and lubricator for additional conditioning. To keep the filter in good working order, routine maintenance is required, such as emptying the collected water and changing the filter element.

2. Regulator: Managing Pressure

The regulator controls the pressure of the air delivered to the pneumatic tools after the air has been filtered. To keep these equipment in good working order and extend their life, consistent pressure is essential.

How It Works:

A knob or screw allows the user to change the air pressure using the regulator’s valve. A diaphragm connected to a spring-loaded mechanism interacts with the air as it flows through, adjusting the valve based on the pressure that has been set. Even when the input pressure changes, this system keeps the output pressure constant. For the tool to work safely and efficiently, the regulator must be adjusted properly.

3. Lubricator: Ensuring Smooth Operation

The lubricant is the last part of an F-R-L system. Its purpose is to reduce friction in pneumatic equipment and increase its lifespan by adding a controlled amount of oil to the cleaned and regulated air.

How It Works:

One method of oil injection in pneumatic systems is to use a venturi system to introduce a fine mist of oil into the airflow. This apparatus takes oil in a bowl and turns it into tiny particles using atomization. A vital lubricant is applied to the interior components of pneumatic tools as the oil-laden air flows through the system. All moving parts are kept well-oiled while the system is operating by this continual lubrication procedure. For optimal operation, it’s important to use the right kind of oil and keep the lubricator filled to the recommended amount.

Conclusion

An essential part of any pneumatic setup, the F-R-L Air Preparation Unit ensures that pneumatic equipment receives consistent and high-quality airflow. Investing in an F-R-L unit is a great way to boost the performance and longevity of your pneumatic machines.

Because of the CKD Air Preparation Unit’s exceptional efficiency and dependability, SS Hussain is the best choice for FRL unit installation. For those who already own them, SS Hussain may also take care of any necessary repairs.