Ever wonder how something as invisible as air gets turned into a powerful force that drives everything from factory tools to refrigeration systems? It all starts with an air compressing unit–a compact powerhouse found in countless industrial instruments across nearly every sector.

These systems aren’t just about blowing air into tires. They’re essential for powering production lines, automating machinery, and maintaining control systems with incredible precision. Understanding how they work isn’t just for engineers–it’s useful for anyone managing, maintaining, or investing in industrial operations.

Let’s break it down.

What Is an Air Compressing Unit?

At its core, an air compressing unit takes ambient air and squeezes it into a smaller volume, increasing its pressure and energy potential. That compressed air is then stored or sent through a system to perform mechanical work–like lifting, pushing, or spinning.

Sounds simple, but there’s a lot going on under the hood.

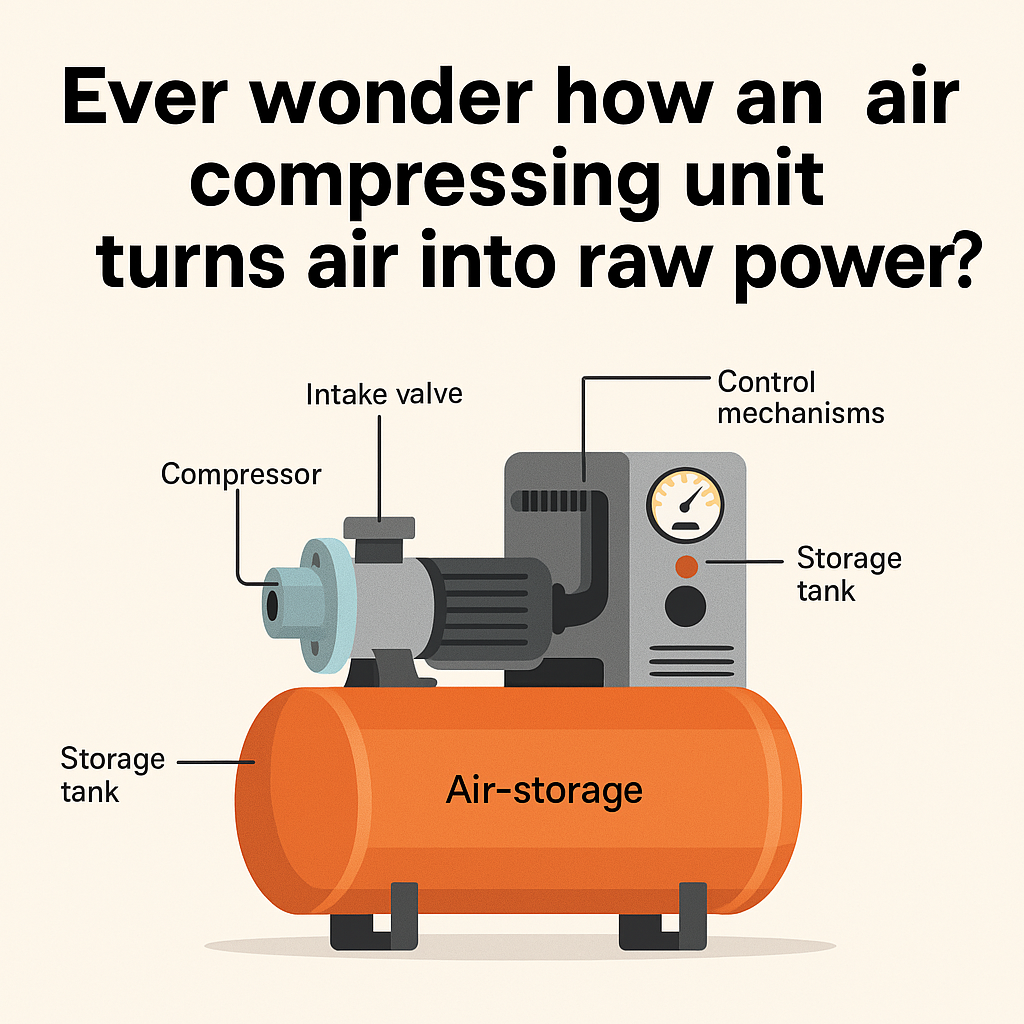

Most air compressing units consist of four main components:

- Intake valve: Draws in air from the atmosphere.

- Compressor: Pressurizes the air using mechanical force.

- Storage tank: Holds compressed air for later use (in many systems).

- Control mechanisms: Manage pressure levels and airflow for efficiency and safety.

Depending on the application, compressors can be small and portable or large-scale systems powering entire plants. Either way, the principle remains the same: convert air into usable energy.

Step-by-Step: How an Air Compressing Unit Works

Let’s walk through the process–step by step–to see how raw air becomes a high-pressure asset.

1. Air Intake

Everything starts with the intake valve. This is where ambient air enters the system. A filter removes dust and debris to ensure the compressor isn’t damaged over time. Clean air is essential–dirty air leads to maintenance headaches and reduced efficiency.

2. Compression Process

Once inside, the compressor gets to work. There are several types of compressors, but they all share the same goal: reduce the volume of air and increase its pressure.

- Reciprocating (piston) compressors use pistons and cylinders.

- Rotary screw compressors use twin rotors.

- Centrifugal compressors use high-speed impellers.

Each type has its own use case depending on the required pressure, flow rate, and duty cycle.

As the air is compressed, it heats up–sometimes significantly. That’s why most units include an aftercooler or intercooler to bring the air temperature back down before storage or distribution.

3. Air Storage (Optional)

Many systems include a storage tank, where compressed air is held until needed. This allows the compressor to operate intermittently while still providing a steady supply of pressurized air.

Think of it like charging a battery. You store energy so it’s available when the system needs it.

4. Pressure Regulation and Distribution

Once the air is pressurized and cooled, control systems manage the flow. Pressure switches, safety valves, and regulators ensure the air is delivered at the right pressure and volume–protecting both equipment and operators.

From here, the compressed air is routed through piping to power tools, automation systems, or other industrial equipment.

Why It Matters

So why go through all this trouble to compress air? Because it’s safe, versatile, and incredibly effective.

Compressed air is often called the “fourth utility” in industrial settings–right alongside electricity, water, and gas. It powers pneumatic tools, actuators, valves, sprayers, and control systems.

Some of its key advantages include:

- No spark risk (ideal for flammable environments)

- High energy-to-weight ratio

- Easily stored and transported

But efficiency is key. Air compression is energy-intensive–typically, only 10–15% of the electrical energy input gets converted into useful compressed air. The rest is lost as heat.

That’s why system design, regular maintenance, and proper sizing are critical. An oversized unit wastes energy. An undersized one struggles to meet demand, leading to pressure drops and equipment wear.

Tip: Always match your air compressing unit to the actual demand of your operations–not just the maximum possible load.

Common Pitfalls to Avoid

Understanding how an air compressing unit works is half the battle. Avoiding these common mistakes can save you time, energy, and costly repairs:

- Ignoring air leaks: Even small leaks can add up to massive energy losses over time.

- Skipping maintenance: Dirty filters, uncalibrated controls, and worn components reduce performance and lifespan.

- Improper sizing: Either too big or too small, the wrong unit drains efficiency and strains your system.

- Inadequate ventilation: Overheating can shorten the life of the compressor and compromise output pressure.

Investing in proper installation, routine inspections, and staff training pays off quickly.

Conclusion

An air compressing unit might not look like much, but behind that unassuming casing lies a system that keeps entire industries moving. From manufacturing to pharmaceuticals, construction to food processing, compressed air is the unsung hero of modern industry.

Understanding how these units work–and how to manage them wisely–helps you get the most out of your operations while keeping energy costs in check.

Of course, the right equipment makes all the difference. If you’re setting up a new system or upgrading an existing one, choosing a reliable air compressing unit is key. SS Hussain supplies durable, high-performance industrial instruments–including air compressors–designed to meet the demands of modern industry.

Explore our range today and find the unit that fits your needs perfectly.