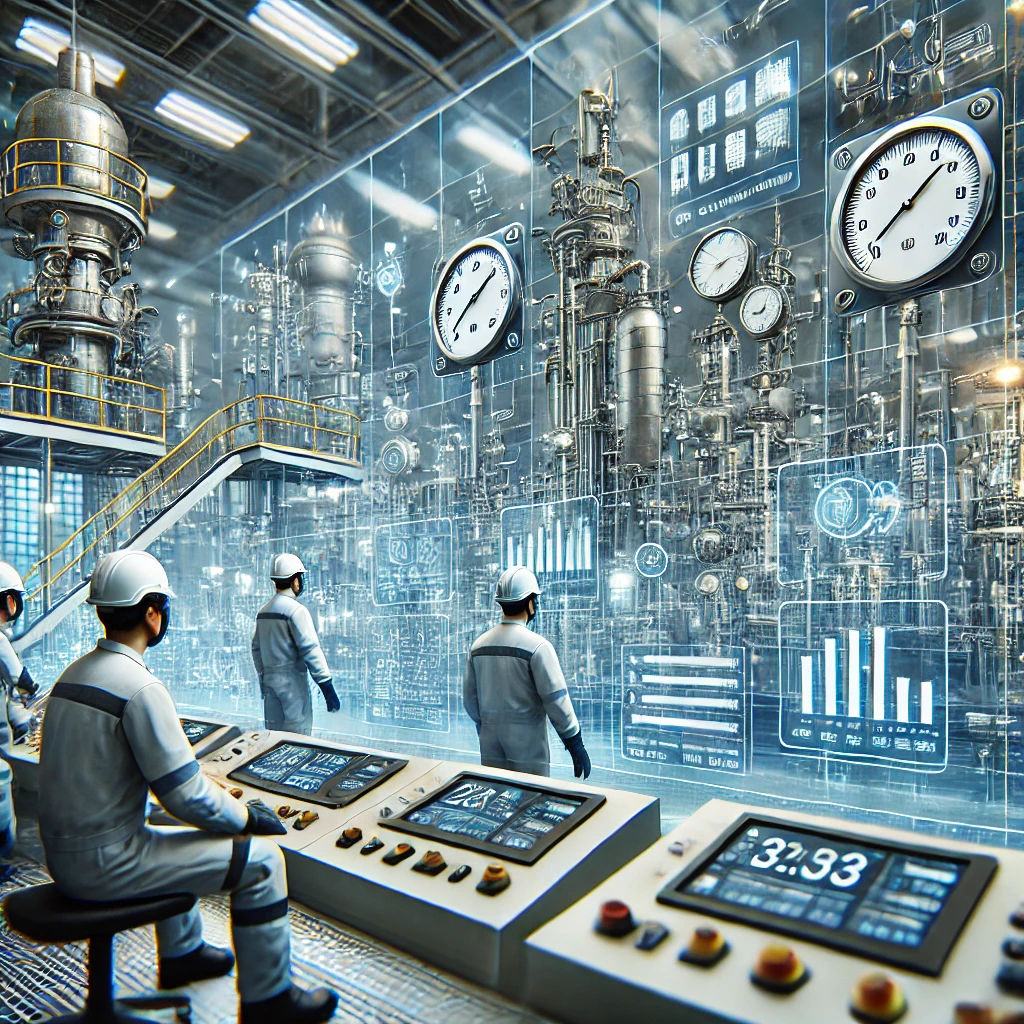

Industrial processes require precision, safety, and efficiency. Even a tiny mistake in pressure, temperature, or flow rate can result in equipment failures, productivity losses, or hazardous incidents in industrial plants, chemical refineries, and oil and gas operations. Here is where industrial instrumentation becomes vital. These instruments guarantee safety, consistency, and industry-standard compliance by helping monitor, control, and automate procedures.

Serious hazards, such as erroneous product quality, regulatory fines, and costly downtime, threaten industries without reliable industrial instrumentation. The correct equipment is crucial for measuring liquid levels using flow meters, air pressure, or operating pneumatic components.

This blog will describe how industrial instrumentation increases safety and quality control and what industries can do to prevent failures.

The Role of Industrial Instrumentation in Safety

1. Preventing Equipment Failures

Neglected equipment failures are a common cause of industrial accidents. Real-time monitoring, made possible by pressure sensors and temperature controls, alerts operators to problems before they cause damage. For instance, a pressure gauge in steam boilers can set off an emergency shutdown in response to too high pressure, preventing an explosion.

2. Detecting Gas Leaks

Toxic or combustible gas leaks could cause fatal events. Gas detectors track the air constantly, spotting hazardous chemicals before they reach threatening levels. A hydrogen sulfide gas detector may sound alarms at oil refineries as the gas concentration rises, preventing lethal exposure.

3. Ensuring Compliance with Safety Standards

Companies must follow EPA (Environmental Protection Agency) and OSHA (Occupational Safety and Health Administration) rules. Frequent calibration and repair of industrial equipment guarantees correct reporting, preventing hefty penalties and closures.

Safety Tip:

Industries should include automated alarm systems with their instruments to improve safety. This guarantees quicker reactions in an emergency and allows real-time notifications through mobile devices.

Industrial Instrumentation & Quality Control

High-quality items are made not just with the finest materials but also with precision throughout the manufacturing process. Minor flaws can cause problems with the goods, refunds, and financial losses. Through stage-of-production monitoring, industrial instrumentation guarantees consistency.

1. Eliminating Human Error

It is easy for human error to creep into manual data collection. Precise readings from automated flow meters, weighing sensors, and temperature controls help to minimize reliance on human calculations. For example, a wrong medication formulation might negatively affect the pharmaceutical sector. Through proper ingredient ratios, automated batch controllers help to avoid such mistakes.

2. Reducing Waste and Improving efficiency

Money goes down the drain when industrial processes go to waste. Industries can get the most out of their resources by using level monitors and smart meters. Food processing industries, for example, utilize moisture analyzers to guarantee ideal water content in goods, thereby preventing spoilage and waste.

3. Enhancing Production Speed

Automated control systems and pneumatic components allow businesses to speed up production without sacrificing quality. For instance, pneumatic actuators provide exact motion in robotic assembly lines, which boosts production and decreases downtime.

Key Industrial Instruments & Their Functions

-

Pressure Gauges

Fluid or gas pressure is essential for monitoring pipelines, boilers, and hydraulic systems. They guarantee good running conditions and help to minimize pressure-related breakdowns.

-

Temperature Sensors

It is utilized in food processing and steel manufacturing sectors to control heating and cooling systems, guaranteeing that goods satisfy accepted standards.

-

Flow Meters

Industries can improve fuel use and discover leaks by measuring the flow rate of gases and liquids.

-

Levels of Sensors

Store tank liquid level monitoring helps to prevent overflows and shortages.

-

Vibration Sensors

It is used in heavy machinery to find early wear and tear, avoiding unplanned breakdowns.

Check out our blog on the top 10 industrial instrumentation used in modern industries.

Conclusion

Safety, quality control, and efficiency in operation all depend on industrial instrumentation. From tracking temperature and pressure to spotting gas leaks and streamlining manufacturing, these instruments guarantee that businesses run as they should.

Industries should prioritize investing in high-quality equipment, maintaining them regularly, and utilizing developing technology for real-time monitoring to avoid failures.

Need reliable industrial instrumentation? SS Hussain offers high-quality controls and measurements. Explore our selection today to improve your industry’s accuracy and safety!