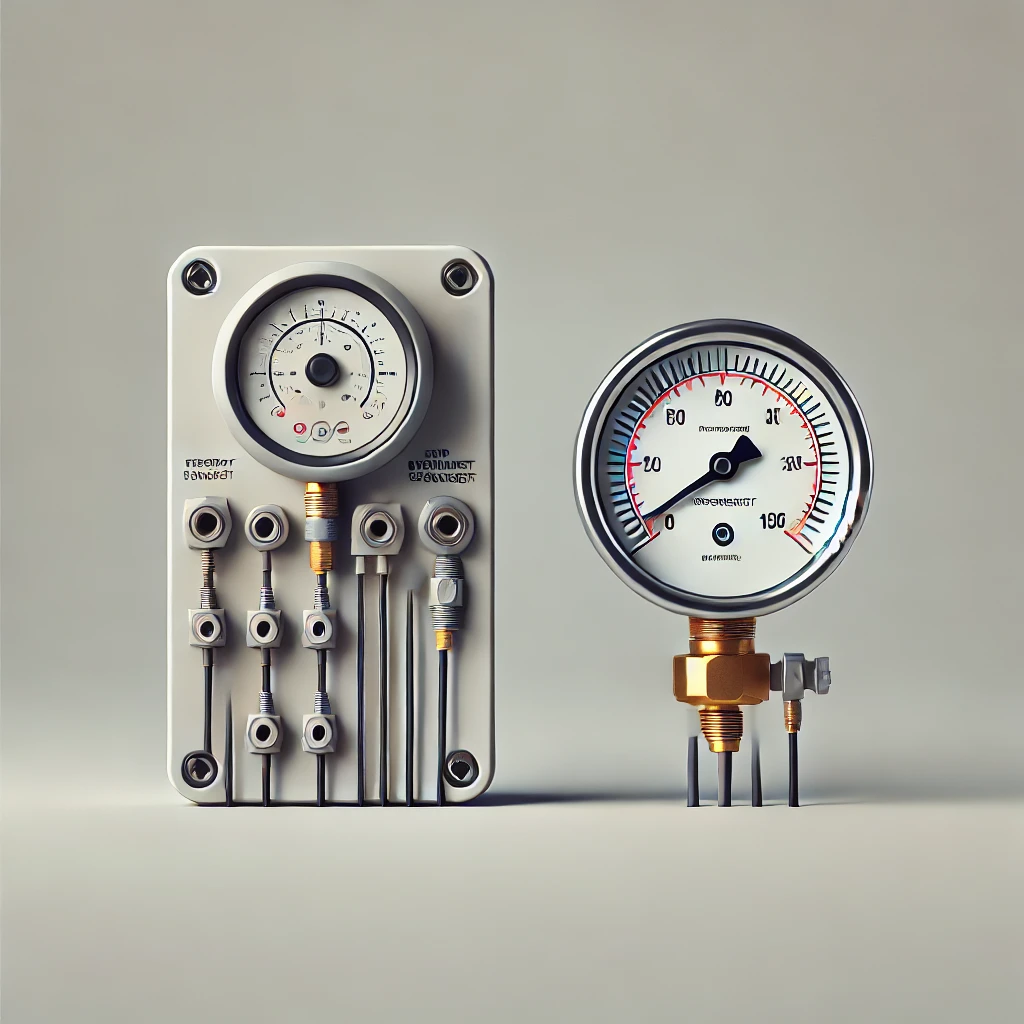

Pressure gauges are essential industrial equipment used in factories. Picking the correct pressure gauge is crucial in maintaining safety and efficiency when working with hydraulic systems, gas pipes or HVAC systems. Although standard pressure gauges are often used for manual readings, electric contact pressure gauges provide automation and control capabilities. If you aren’t sure which one is best for you, this guide will explain everything in detail.

What Makes an Electric Contact Pressure Gauge Different?

Electric contact pressure gauges are similar to traditional gauges, except they have electrical connections that can activate pumps, shut off systems, or sound alarms when the pressure exceeds a certain level. This makes it perfect for controlling pressure automatically in places like power plants, chemical plants, and oil and gas.

Electric contact gauges may be integrated with control systems for greater efficiency and security than conventional gauges requiring manual monitoring. They prevent system failures by sending real-time alerts when pressure fluctuates beyond safe limits. However, they need a power source and periodic maintenance to keep the electrical contacts working correctly.

Understanding Standard Pressure Gauges

Standard pressure gauges typically use a dial and a Bourdon tube to measure and show pressure levels. Industries such as HVAC systems, water treatment facilities, and hydraulic gear can benefit from its simplicity and affordability because it functions without electrical components.

Since they don’t run on power, these gauges are dependable and perfect for settings with little access. They also demand little upkeep and are robust. But they aren’t automated, so you must watch them by hand, which isn’t always doable in a fast-paced industrial environment.

Electric Contact Pressure Gauge vs. Standard Gauge: Which One to Choose?

Accuracy & Monitoring

Standard gauges: Standard gauges need manual readings. Hence, someone has to verify and analyze the pressure values frequently. While they lack real-time alarms, they are appropriate for use when occasional monitoring is sufficient.

Electric Contact Gauge: Electric contact gauges track real-time and immediately set alarms when pressure levels vary. They are perfect for use and require continual monitoring and fast reaction.

Automation Needs

Standard Gauge: Standard Gauges are more appropriate for systems where automated pressure management is not required as they depend on hand observation. In installations where regular pressure checks are enough, they perform effectively.

Electric Contact Gauge: Electric contact gauges work with automatic control systems, so less work must be done by hand. They can operate pumps, set alarms, or turn off machinery when pressure levels exceed certain limits.

Durability & Maintenance

Standard Gauge: Standard gauges are renowned for low maintenance and long-lasting performance. They are dependable in demanding conditions when electrical access is limited, as they do not run on power.

Electric Contact Gauge: Although long-lasting, electric contact gauges need routine servicing to inspect the electrical connections and guarantee accurate readings. They have advanced features but must be adequately maintained to stay accurate.

Cost Considerations

Standard Gauge: Standard gauges are reasonably priced and efficient for essential monitoring. Businesses seeking a straightforward and affordable solution that doesn’t need automation are the go-to option.

Electric Contact Gauge: These gauges cost more upfront, but they are worth it because they make things safer, more efficient, and easier to automate. They help to prevent system breakdowns, therefore lowering long-term running expenses.

Wrapping It Up

It depends on what you must pick between an electric contact pressure gauge and a regular one. If you need remote monitoring, safety elements, and automation, an electric contact pressure gauge is ideal. But if you’re looking for a simple, affordable solution for manual tracking, a standard pressure gauge will work just fine.

Both have their place in industrial equipment, so assess your requirements before deciding. If you need expert guidance, SS Hussain offers a range of high-quality pressure gauges and industrial equipment to suit various applications. View our collection now to identify the right solution for your requirements!