In the world of industrial processes, pressure gauges play a crucial role in ensuring safety, efficiency, and optimal performance. These devices provide vital information about the pressure of fluids and gasses within various systems, enabling operators to monitor and control pressure levels.

From manufacturing plants to chemical processing facilities, pressure gauges are indispensable tools that empower operators to make informed decisions, prevent accidents, and maintain the integrity of industrial processes. In this blog post, we will delve into the workings, applications, and importance of pressure gauges in various industries.

Pressure Gauges: Monitors Of Industrial Performance And Safety:

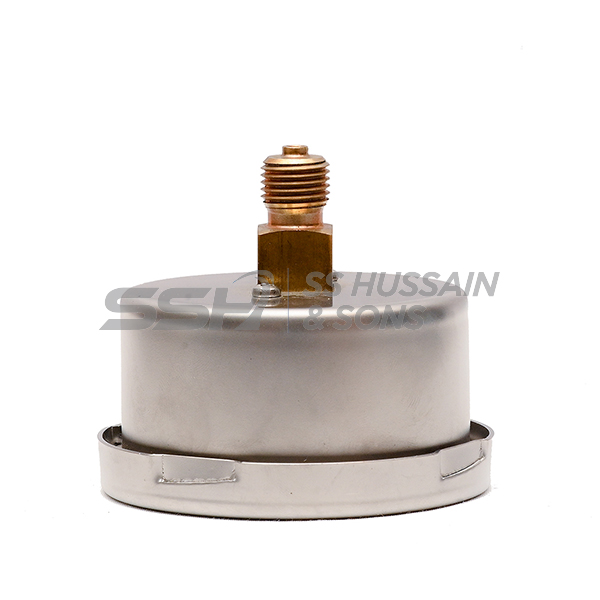

Pressure gauges serve as vital monitors of industrial performance and safety, playing a crucial role in a wide range of applications. These devices accurately measure and display the pressure of liquids, gasses, and vapors within industrial systems. By providing real-time pressure readings, they enable operators to maintain optimal operating conditions and ensure safety protocols.

Pressure gauges are used in various industries, including manufacturing, oil and gas, chemical processing, and power generation. They help detect abnormal pressure fluctuations, leaks, and potential system failures, allowing for timely interventions to prevent accidents and costly downtime. Furthermore, pressure gauges contribute to the efficient operation of machinery, optimizing energy consumption and minimizing waste.

Through their durable construction, precise measurements, and clear visual display, pressure gauges enhance industrial efficiency, productivity, and safety.

The Crucial Role Of Pressure Gauges In Industrial Processes:

Pressure gauges play a crucial role in industrial processes, serving as essential tools for monitoring and controlling pressure levels. These devices accurately measure the pressure of liquids, gasses, and vapors within various systems, ensuring optimal operating conditions and preventing potential hazards.

In industrial settings such as manufacturing plants, refineries, and chemical processing facilities, pressure gauges provide real-time data that enables operators to detect abnormalities, leaks, or system failures. By promptly identifying deviations from desired pressure levels, these gauges allow for immediate corrective actions, preventing accidents, equipment damage, and costly downtime.

Pressure gauges also aid in maintaining process efficiency and optimizing energy consumption. They help operators ensure that machinery operates within safe pressure ranges, reducing waste and improving productivity. With their reliable performance and clear visual display, pressure gauges empower industrial processes by enhancing safety, productivity, and overall operational efficiency.

How To Maintain The Reliability And Accuracy Of Pressure Gauges?

To maintain the reliability and accuracy of pressure gauges, regular maintenance, and calibration are essential. Here are some key steps to follow:

- Scheduled Inspections:

Conduct routine visual inspections to check for physical damage, such as scratches or dents, that may affect gauge performance.

- Calibration:

Periodically calibrate pressure gauges to ensure accurate readings. This can be done using specialized calibration equipment or by a certified calibration service provider.

- Zero Adjustment:

Verify and adjust the zero point of the gauge regularly, ensuring it accurately reads zero when there is no pressure applied.

- Protection from Vibrations:

Install pressure gauges on the locations for excessive vibrations, from this accuracy will never affect.

- Sealing and Leak Checks:

Inspect and replace any damaged or worn-out seals or gaskets to prevent leaks that can affect gauge readings.

By following these maintenance practices, industrial facilities can ensure the reliability and accuracy of pressure gauges, enabling them to make informed decisions based on precise pressure measurements.

Understanding The Different Types And Applications Of Pressure Gauges With SS Hussain

SS Hussain is an experienced professional in the field of instrumentation and control systems. With a strong background in industrial processes and pressure measurement, S.S Hussain has extensive knowledge of different types and applications of pressure gauges. Their expertise lies in selecting and recommending the most suitable pressure gauges in Pakistan based on specific requirements and industry standards.

SS Hussain’s expertise goes beyond pressure gauges, encompassing a wide range of instrumentation devices used in industrial settings from brands like Kipinago and True Tellers which are owned by them. At the same time, they also work closely with international brands like Wika, Airtac, Shavo, Festo, EMC، YPC, and others to provide customers with a diverse range of high quality products and meet their specific requirements.

SS Hussain brands are well-known for their exceptional products in the construction and industrial sectors.

- S.S Hussain & Sons offers a comprehensive range of construction materials and supplies, including steel, cement, and other building components.

- Brand Kipinago specializes in industrial machinery and equipment, providing innovative solutions for manufacturing and automation processes.

- Brand True Teller specializes in precision measuring instruments, offering accurate and reliable measurement solutions.

- Festo is renowned for its expertise in pneumatic and automation technology, providing advanced and efficient solutions for industrial processes.

- Airtac is a leading manufacturer of pneumatic components, valves, and actuators, known for their quality and reliability.

- Shavo offers a wide range of pressure control and measurement products, catering to diverse industrial applications.

- EMC specializes in electrical and electronic components, providing cutting-edge solutions for various industries.

- YPC offers a comprehensive range of pneumatic products and solutions for industrial automation.

By partnering with these and several other amazing brands, SS Hussain ensures access to a wide selection of high-quality products and solutions across different industries.

SS Hussain possesses a deep understanding of process control systems, measurement techniques, and safety protocols. With their meticulous approach and attention to detail, SS Hussain ensures that pressure gauges in Pakistan are properly installed, calibrated, and maintained for reliable and accurate performance.

FAQS:

- What is a pressure gauge?

A pressure gauge is a device that measures and displays the pressure of a fluid or gas.

- Where can I buy pressure gauges in Pakistan?

You can buy the best pressure gauges in Pakistan from S.S Hussain & Sons.

Conclusion:

From their accurate measurements to real-time data display, pressure gauges empower operators to make informed decisions and take timely actions. By detecting abnormalities, preventing accidents, and optimizing energy consumption, these devices ensure efficient and safe industrial processes. Whether it’s in manufacturing, oil, and gas, or chemical processing, pressure gauges are indispensable tools that enhance productivity, minimize downtime, and safeguard both workers and equipment. As technology advances, pressure gauges will continue to evolve, adapting to the ever-changing demands of the industrial world.[/vc_column_text][/vc_column][/vc_row]