Electromechanical solenoid valves are a type of valve that transform electrical energy into mechanical energy. Their primary objective is to manage gas or liquid flow, removing the need for an engineer to manually operate the valve and saving time and money in the process.

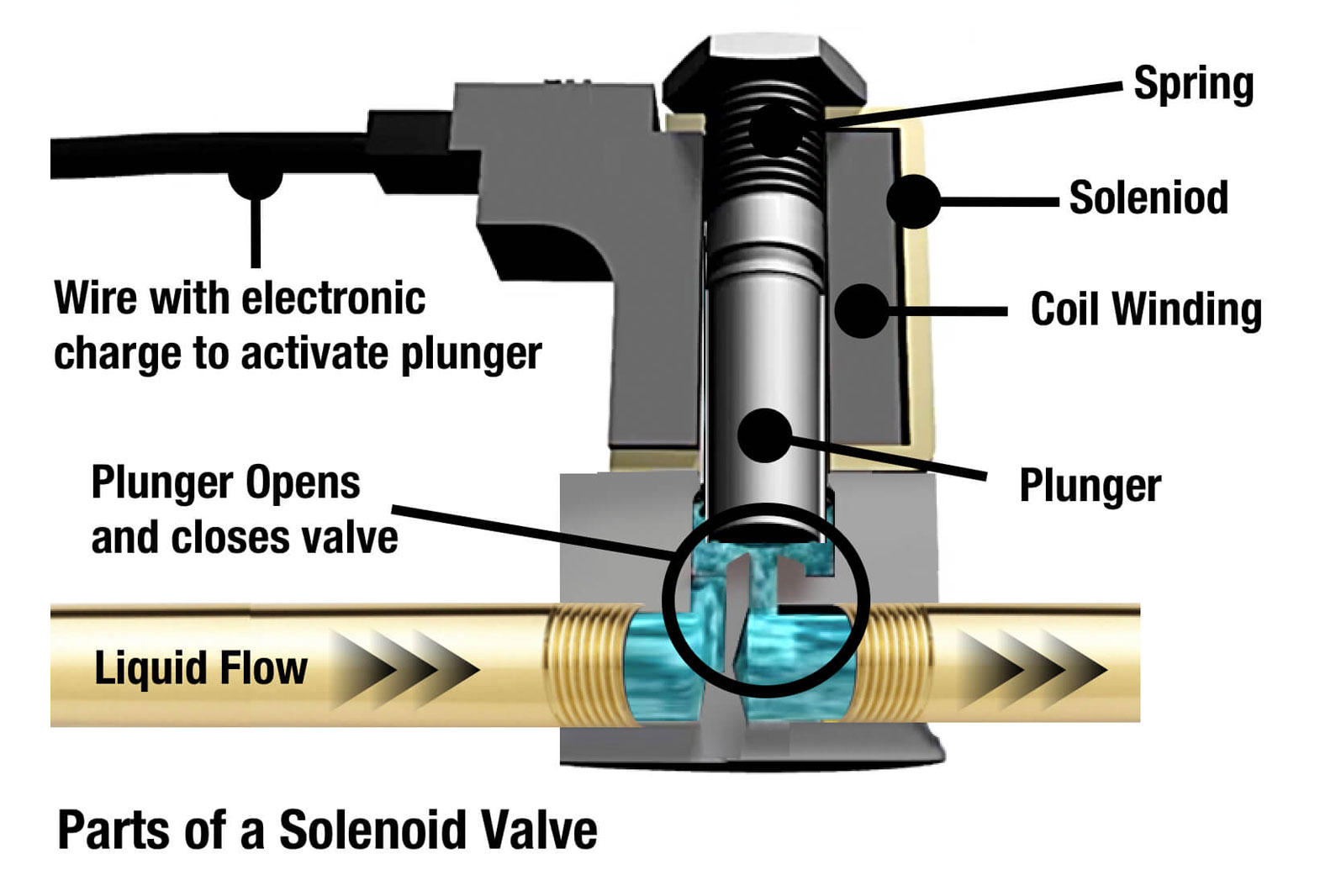

An electromechanical isolation valve known as a solenoid control valve enables an electrical device to regulate the flow of gas or liquid. The solenoid valve’s coil on the electrical device receives a current from the electrical device, creating a magnetic field that moves a metal actuator. The solenoid valve’s internal valve and the actuator are mechanically connected. The solenoid valve then causes this mechanical valve to open or close, allowing a liquid or gas to pass through or be blocked. When the current flow is stopped in this control system, a spring is employed to bring the actuator and valve back to their resting positions. When an electric current passes through a solenoid valve’s coil, a magnetic field is created. The ball valve, which can change states to open or close the device in the fluid direction, is activated by the magnetic field created. When electrically charged or discharged, solenoid valves are control devices that either shut off or permit fluid flow. An electromagnet serves as the actuator inside a solenoid valve. A plunger or pivoting armature is pulled by an electrified magnetic field in opposition to the force of a spring. The plunger or pivoting armature moves back to its initial position by the spring action when the device is de-energized. Direct-acting valves, internally piloted valves, and externally piloted valves are differentiated based on the manner of actuation. The quantity of flow pathways or “ways” or port connections is another defining characteristic. A solenoid that has been initiated by an electrical signal is used to open and close solenoid valves. The following five types of solenoid valves are used in the majority of industrial applications.

• The two-way solenoid valves: This kind of solenoid valve, which is used to allow and stop fluid flow, typically has one intake and one exit. This type has two different types of operations: “usually closed” and “normally open.”

• The three-way solenoid valves: These valves typically feature two orifices and three pipe connections. Both orifices are closed when one is open, and vice versa. They are frequently employed to alternately apply pressure to an exhaust pressure from a single-acting cylinder or a valve actuator. These valves might be universal, typically closed, or normally open.

• Four-way solenoid valves: These valves contain four or five ports, which are pipe connections. One of the ports is a pressure inlet, two are cylinder ports that supply pressure to the double-acting cylinder or actuator, and one or two outlets let the cylinders’ built-up pressure out. They come in single solenoid, dual solenoid, or single air operator configurations.

• Direct mount solenoid valves: These solenoid valves, which come in two-, three-, and four-way varieties, are made to be gang mounted into various numbers of valves. Any assortment of universal, typically closed, or normally open valves may be grouped. Standard solenoid valves in this series have had their pipe connections and mounting arrangements swapped out for a mounting arrangement that enables each valve to be mounted directly to an actuator without the need for hard pipework or tubing.

• Main fold valves: A matrix of solenoid valves installed in modules. They have adjustable legs along one direction making up a solenoid valve manifold. The quantity of valves relies on the components that must be connected as well as the roles that each of these components must play. On the installation face of the manifold, several solenoid valves are positioned and organized, and a board with an electrical circuit is built for feeding these solenoid valves. Both a solenoid operating portion for powering the valve member and a valve portion containing the valve member are included in each solenoid valve. Under the solenoid operational portion of the manifold’s initial side face, the board is mounted. Feeding connectors and signaling LEDs are placed in locations on the board that corresponds to the individual solenoid valves, allowing the board to be attached and detached while leaving the solenoid valves mounted on the manifold. Each feeding connector is positioned so that, when the solenoid valve is mounted on the manifold, it is linked to a receiving terminal of the solenoid valve in a plug-in fashion. Each indication light is placed so that, when the solenoid valve is still installed on the manifold, it may be seen from above the solenoid valve. This manifold enables the modular centralization of the functions of one or more tanks, improving system efficiency and level of process control. An automated replacement for flexible hoses and flow divert panels with changeover bends is the solenoid valve manifold. The tank or working line is connected to as many valves as the element needs to complete the functions. No manual labor is necessary. Accidents eliminate the risk thanks to the automation of the process. The majority of flow control applications need to start or stop the circuit’s flow to regulate the system’s fluids. Typically, an electronically controlled solenoid valve is employed for this. Solenoid valves can be placed in remote areas and conveniently operated by basic electrical switches because they are solenoid actuated. The most often utilized control components in fluidics are solenoid valves. They are frequently used to mix, dose, release, and shut off fluids. They have a wide range of applications as a result. In general, solenoids provide a small design, low control power, extended service life, high dependability, and quick and safe switching. Any application that requires the control of clean process media, such as exceptionally clean liquids, gases, or light oils. Since many process lines either require flow or no flow, simple on/off valves are the most common. In industries and plants without access to compressed air, solenoid valves can be employed. They do not occupy nearly as much space as larger valves like electrically actuated ball valves, but they can also be employed in their stead. In comparison to previous valve technologies, the operation is also a lot faster. Other solenoid-controlled valves employ more sophisticated technology. This then allows for proportional flow or pressure control in response to changing input signals. To maintain the proper working conditions, another component further downstream needs a particular pressure or flow. These valves are used in all sorts of industries. Their biggest advantage is being controlled automatically, which eliminates the need for extra men to operate them. Different types of valves have specific designs to suit the specific applications they will be used in.

SS Hussain & Sons is the leading source of temperature and pressure instrument solutions for critical Processes and Industrial/OEM (original equipment manufacturer) applications across the globe. If you are looking for a reliable solution in the fields of pneumatics, industrial automation, and gauges in Karachi, SS Hussain & Sons should be your best choice.