Ever wondered how industries measure the flow of liquids without any moving parts—or even touching the fluid itself? That’s where the electromagnetic flow meter steps in. It’s one of the most reliable tools for tracking liquid flow in everything from water treatment plants to food processing lines—and a key component in many industrial solutions.

When precision matters and downtime isn’t an option, this meter quietly delivers results that keep operations running smoothly. If you’re in the world of industrial flow measurement, it’s a name worth knowing—and understanding.

Let’s take a closer look at what an electromagnetic flow meter really does, how it works, and why it’s often the first choice in demanding applications.

What Is an Electromagnetic Flow Meter?

Electromagnetic flow meter—often called a mag meter—is a device used to measure the flow rate of conductive liquids. It doesn’t rely on mechanical components or pressure changes. Instead, it uses a clever combination of magnetism and electricity.

That makes it ideal for applications involving:

- Water and wastewater

- Slurries and corrosive fluids

- Food-grade or chemical liquids

- Pulp and paper processes

Unlike other meters that might get clogged or wear down over time, mag meters have no moving parts, meaning lower maintenance and longer life–especially in dirty, abrasive, or high-volume environments.

How Does an Electromagnetic Flow Meter Work?

The principle behind it is surprisingly straightforward, rooted in Faraday’s Law of Electromagnetic Induction. Here’s the short version:

When a conductive liquid flows through a magnetic field, it generates a voltage. That voltage is directly proportional to the velocity of the fluid. By measuring that voltage, the meter can calculate how much liquid is moving through the pipe—and how fast.

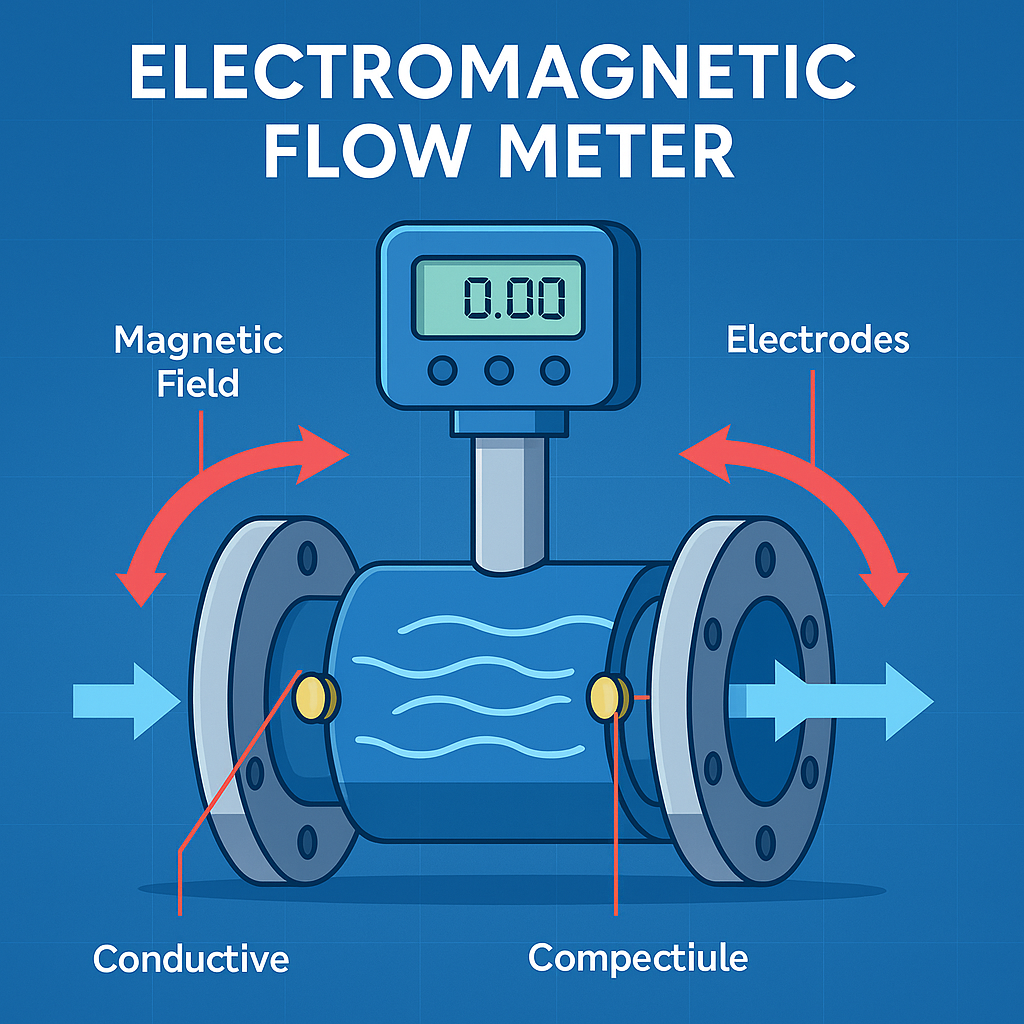

Here’s a step-by-step breakdown of what’s happening inside the meter:

- Magnetic Field: Coils in the meter create a magnetic field across the flow tube.

- Conductive Liquid: As the liquid flows through the magnetic field, it generates a tiny voltage.

- Electrodes: Sensors (electrodes) on the pipe walls detect this voltage.

- Signal Processing: The meter’s electronics process the signal and convert it into a readable flow rate.

That’s it. No turbines. No paddles. No obstructions. Just fast, accurate measurement of flow.

Why Use an Electromagnetic Flow Meter?

There’s a reason electromagnetic flow meters are used in so many industries—they offer several practical advantages that make them ideal for challenging environments.

1. Highly Accurate

Mag meters offer accuracy within ±0.2% to ±0.5%, even in turbulent or irregular flows. That level of precision helps maintain process control, reduce waste, and ensure quality standards are met.

2. Zero Pressure Drop

Since there’s nothing obstructing the flow, there’s no added resistance in the system. That means no energy loss, reduced wear and tear, and more efficient operation overall.

3. Low Maintenance

No moving parts means fewer things to fail. Mag meters are especially useful in systems handling dirty or abrasive fluids where other meters might jam or corrode.

4. Suitable for Large Pipes

Electromagnetic flow meters scale well. They can be installed in small pipelines or large-diameter systems in utilities and heavy industry.

5. Bi-Directional Flow Measurement

Need to track flow in both directions? No problem. Mag meters handle that seamlessly, making them versatile across complex piping layouts.

Things to Keep in Mind Before Selecting a Mag Meter

Despite their immense usefulness, electromagnetic flow meters are not a universally applicable solution. Here are some key considerations:

Conductive Fluids Only

They only work with liquids that conduct electricity—like water-based solutions, slurries, and acids. They won’t work with non-conductive fluids like oil or gas.

Proper Grounding Is Critical

A mag meter’s accuracy can be affected by electrical noise or grounding issues. Make sure your system is properly grounded during installation.

Straight Pipe Requirements

Like most flow meters, mag meters need straight pipe runs before and after the device (typically 5–10 pipe diameters) to ensure accurate readings.

Liner and Electrode Material

Depending on the fluid type, you’ll need to choose compatible materials. For example:

- Teflon or PTFE liners for corrosive chemicals

- Stainless steel or Hastelloy electrodes for aggressive media

These details matter when you’re aiming for reliability in long-term operations.

Common Applications Across Industries

Electromagnetic flow meters aren’t limited to one niche—they’re everywhere. Here are some real-world applications:

- Municipal water systems: Measuring flow in treatment plants and distribution lines

- Food & beverage: Monitoring liquids like juice, dairy, or syrup with hygienic fittings

- Mining & minerals: Handling thick, abrasive slurries with high solids content

- Chemical manufacturing: Safely tracking caustic or acidic fluids

- Pharmaceuticals: Maintaining flow consistency in clean environments

When accuracy and durability are non-negotiable, mag meters often come out on top.

Conclusion

The electromagnetic flow meter is one of the most efficient and low-maintenance tools available for liquid flow measurement—especially when dealing with aggressive, conductive, or high-volume fluids. Its non-intrusive design, combined with robust accuracy, makes it a trusted choice in countless industrial settings.

Thinking of upgrading your flow measurement system? SS Hussain offers high-quality electromagnetic flow meters built for precision and long-term performance.

Explore our range today and find the right solution for your application.